4680The battery strikes’╝īUnbelievable Tesla

Under the wave of electrification’╝īAny disturbance in the lithium battery industry has been infinitely amplifiedŃĆéRecent’╝īAs the time for the 4680 battery to become available is approaching’╝ī4680Related sectors of the battery began to restlessŃĆé

Last September’╝īWe are the first time after the release of TeslaŌĆÖs "Battery Day"’╝īJust published an article to interpret the technical content of the 4680 batteryŃĆéSo what impact will the final mass production of 4680 batteries have on the power battery landscape?’╝īThis article attempts to make an interpretation based on the existing information’╝īFor your referenceŃĆé

Don't myth Tesla

As the standard bearer of new energy vehicles’╝īTesla is the king of topics’╝īAnything that involves Tesla’╝īMany followers first came to Tesla's sideŃĆéFrom the localization of Model 3 to Model Y price reduction’╝īIt seems that the market has qualitatively determined the ending in advanceŃĆéThis is not’╝īRecently, the news that Tesla is about to mass produce 4680 batteries has once again become a hot topicŃĆé

It is undeniable that Tesla is the leader of new energy vehicles’╝īRegardless of the sales or its in the Sanden systemŃĆüSmart cockpitŃĆüThe technical capabilities of autonomous driving are industry-leadingŃĆé

but’╝īmost of the time’╝īWe are too mythical TeslaŃĆé

When Tesla was going to enter China’╝īMany people who don't know the truth yelled the sharks’╝īWorry about the living space of local brands and new car manufacturersŃĆéNow it seems’╝īDomestic car companies and new car manufacturers have not only survived’╝īStill alive’╝īThe monthly sales of "Wei Xiaoli" has already exceeded 10,000’╝īBecome the backbone of domestic smart electric brandsŃĆé

Excluding the subjective level’╝īMusk is radical and even sometimes unreliable style should let the market calm down first’╝īDon't rush to set the tone for the success or failure of the 4680 batteryŃĆéTechnical route for power battery’╝īThe cylindrical battery dominated by Tesla has not become mainstream’╝īin addition’╝īThe high-nickel ternary battery that Musk had strongly admired earlier did not form an overwhelming advantage.’╝īOn the contrary, lithium iron phosphate is highly sought after’╝īEven Tesla itself launched the Model 3 lithium iron phosphate versionŃĆé

There are also some examples that can be used as evidenceŃĆéMusk has repeatedly talked about the value of Bitcoin in public’╝īJanuary of this year’╝īTesla bought $1.5 billion worth of Bitcoin’╝īIt's March’╝īMusk said on Twitter’╝īTesla now accepts Bitcoin paymentsŃĆéBecause of the heat of Tesla and Musk’╝īBitcoin, already on the cusp of the storm, once again ushered in a price surgeŃĆé

The end result was unexpected’╝īOnly two months have passed’╝īIt's May 12’╝īMusk "turned his face" and said that because Bitcoin consumes too much power’╝īNot in line with the concept of sustainable development’╝īTesla will no longer accept Bitcoin payments’╝īInvite Bitcoin's crashŃĆé

You know that Tesla has already sold $272 million worth of Bitcoin in the first quarter’╝īAnd made about 101 million U.S. dollars in profit from itŃĆéThis wave of Musk's operation is somewhat inconsistent with his "Iron Man" persona.ŃĆéLetŌĆÖs look at TeslaŌĆÖs quarterly report this year’╝īIts profit in the first quarter was $438 million’╝īAn increase of 16 million U.S. dollars from last year’╝īIn fact, Tesla's sale of Bitcoin and electric car credits accounted for a large part of the incomeŃĆé

And Musk has vowed to guarantee the L5 level of autonomous driving technology has not been launched.’╝īThe time to market for electric pickups has been delayed again and againŃĆéAnd the workmanship of Tesla vehicles is often complained about.’╝īSimple interiorŃĆüRough workmanshipŃĆüRandom materials are no longer newŃĆéAlthough the current Model Y has been greatly improved’╝īBut compared with domestic cars of the same level’╝īStill inferiorŃĆé

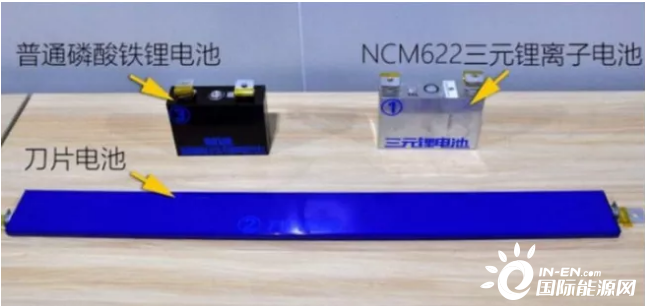

Closer to home’╝īBack to the 4680 battery’╝īAfter all, the main change of the Tesla large cylindrical battery is the structural innovation(But don't ignore the foreshadowing of solid-state batteries at the level of electrochemical innovation)’╝ī4680The battery and BYD's blade battery have a lot in common’╝īThe blade battery is equivalent to making the original square battery longer’╝ī4680The battery enlarges the original "little man" into a "short and fat man" (limited to the height of the chassis’╝īThe height of the cylindrical battery is limited)ŃĆé

figure 1’╝ÜSize comparison of blade battery and square battery’╝īsource’╝ÜThe internet

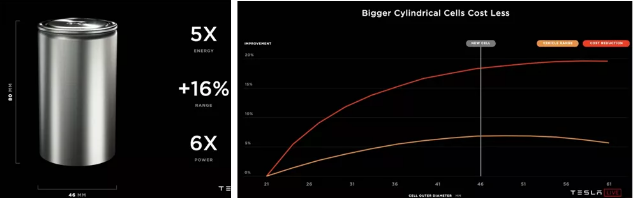

Theoretically’╝īCylindrical batteries can be made more "fat"’╝īThe capacity of a single battery will be larger (the volume of the 4680 battery is about 5.5 times that of the 2170 battery)ŃĆéBut the battery is not big enough’╝īAlso consider the difficulty of manufacturingŃĆüFast charging performanceŃĆüHeat dissipation and other aspects’╝īOtherwise, the whole chassis is just a battery’╝īTeslaŌĆÖs most recent choice is a diameter of 46mmŃĆé

Others say that the cost per kilowatt hour of the 4680 battery has dropped by 14%’╝īWill Tesla continue to cut prices? In fact, it is natural that the PACK cost of the battery pack will decrease after the battery is enlarged.ŃĆéThis is like replacing 500ml of mineral water with a 2.5L large bottle.’╝īNatural bottle capŃĆüPackaging boxes and other materials will be reducedŃĆé

It is worth noting that’╝īBattery companies are still leaders in battery innovation’╝īThe CTP technology launched by CATL as early as 2019 has achieved a 40% reduction in partsŃĆüStructural innovation to increase energy density by 15%ŃĆéAnd CTC technology’╝īMany domestic companies have already begun to deployŃĆéIn the author's opinion’╝ÜInnovation for 4680 cylindrical battery’╝īCan be positive and optimistic’╝īBut donŌĆÖt get too excited because of TeslaŃĆé

figure 2’╝ÜTesla chose 46mm diameter as the "upgraded version" of the 2170 cylindrical battery’╝īsource’╝ÜTesla

but’╝īPower battery is one of the important components of electric vehicles’╝īEvery innovation deserves attentionŃĆéTherefore, it is necessary for us to analyze the innovation of 4860 battery in detail.ŃĆé

4680Extreme manufacturing behind the battery

[1] Tesla's "infinite ear" technology

From a manufacturing perspective’╝īAny power battery company can make cylindrical batteries up to 46mm in diameter’╝īBut after the battery gets bigger’╝īProblems such as fast charging and heat dissipation follow’╝īThis is the real headache’╝īAnd the source of this pain comes from the extreme earsŃĆé

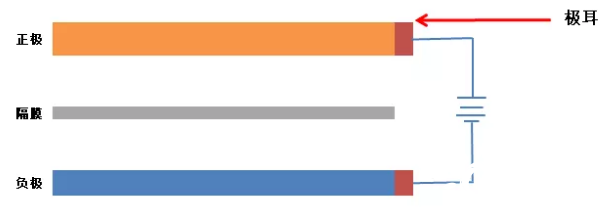

As the name suggests’╝īThe tabs are the "ears" of the positive and negative poles of the battery’╝īIt is a metal conductor that draws the positive and negative poles from the battery core’╝īIt is the contact point between the battery and the external circuit during charging and dischargingŃĆéThis contact point is not the copper sheet on the outside of the cylindrical battery we saw’╝īBut a connection inside the battery’╝īUsually it is combined with the positive and negative current collectors (aluminum foilŃĆüCopper foil) welded togetherŃĆé

image 3’╝ÜSchematic diagram of lithium battery lugs’╝īsource’╝ÜThe internet

Specific to the battery charging and discharging process’╝īThe electrons reach the tabs welded with the current collector of the battery after traversing the entire battery.’╝īAnd then through the external wire to reach the other poleŃĆéWorking on battery’╝īThe flow of electrons can easily lead to excessive local heat at the welding joint of the tab’╝īIn addition, the contact point is small’╝īNot enough space for heat dissipation’╝īThis has always been a bottleneck for battery safety’╝īThe current fast charging is also subject to extreme earsŃĆé

In fact, battery companies all know that cylindrical batteries are going to be large-scaled’╝īBut after the cylindrical battery gets bigger’╝īThe distance the electron needs to traverse grows up’╝īResistance also increases with distance’╝īThe fever problem mentioned above has become more seriousŃĆé

Figure 4’╝ÜSchematic diagram of the internal lithium battery’╝īsource’╝ÜDamask Research Institute

Then’╝īWhat "black technology" does Tesla use to solve this problem? The path is nothing more than shortening the distance’╝īIncrease contact surfaceŃĆéTesla plans to change the structure of the lug’╝īLet the electrons be directly on the cell current collector and cover plateŃĆüConduction between shells’╝īShorten the internal transmission distance of electrons’╝īAt the same time, the contact method of the tabs has also changed from point contact to surface contact’╝īGreatly increase the heat dissipation areaŃĆé

Speaking of here’╝ī4680The basic principle of the endless ear technology has been clear’╝īThe so-called non-polar ears are actually all-polar ears’╝īThis is just MuskŌĆÖs word gameŃĆéAnd this technique’╝īIt is also one of the biggest changes in the 4680 large cylindrical battery’╝īWorth knocking on the blackboardŃĆé

Figure 5’╝ÜTesla full lug technology’╝īsource’╝ÜJindu Research Institute

It is worth mentioning that’╝īATL, the "predecessor" consumer lithium battery leader in the Ningde era, had patented lithium battery multi-pole technology as early as 2015 to reduce battery internal resistanceŃĆé

This all-pole/no-pole technology’╝īIt is also the biggest change in the internal structure of the 4680 battery’╝īCan effectively solve the current problem of fast charging and heatingŃĆéBut with it’╝īThe difficulty of manufacturing has also increased exponentially’╝īBattery companies need to weld the tabs with lasers’╝īThe actual production requires extremely high manufacturing capacity and equipmentŃĆé

until now’╝īTesla has not completely solved the problem of the yield of the lug processing.’╝īThis is why the mass production time of the promotion has to wait until 2022ŃĆé

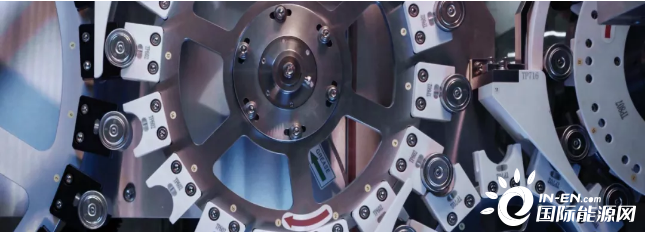

For all-pole technology’╝īAnother layer of meaning may lie in’╝īWhen the cylindrical battery is made into all-pole ears’╝īThe cylinder winding process does not require frequent start and stop (when the battery is circulating in the production system’╝īIt must stop at the position of the tab in real time)’╝īCan achieve true assembly line production’╝īThis will significantly increase production efficiency’╝īreduce manufacturing costŃĆé

Image 6’╝ÜCylindrical battery production process’╝īsource’╝ÜTesla

[2] Electrode dry process

The wet process of normal battery production is to combine electrical grade materials with solventsŃĆüWater etc. mixed into slurry’╝īThen apply on aluminum foilŃĆüAbove the copper foil’╝īAfter tens of meters of drying equipment, compact to the required thicknessŃĆéAnd TeslaŌĆÖs dry process is to directly dry mix the materials’╝īNo solvent mixing’╝īThen press the mixed powder on top of the metal pool’╝īThe advantage is that it eliminates the need for drying and solvent recovery processesŃĆéSwitching between wet and dry methods’╝īFor friends who are familiar with industrial manufacturing’╝īShould be familiarŃĆé

But the above seemingly simple things are very difficult to accomplish’╝īHow to achieve material uniformity in dry mixing’╝īHow to ensure adhesion after compaction’╝īThese pair of craftsŃĆüEquipment is severely testedŃĆéIf this technology achieves’╝īThe simplification of the process reduces the manufacturing cost and environmental protection cost of the 4680 battery’╝īAt the same time, the initial investment cost and land occupation cost of the factory are also reduced accordingly (the drying line is tens of meters long)’╝īWill benefit the further development of the new energy automobile industry’╝īThis kind of innovation is indeed worthy of recognitionŃĆé

In fact’╝īTesla has not been able to achieve a dry manufacturing process before’╝īUntil Tesla acquired the super capacitor company Maxwell at a premium in 2019ŃĆéMuskŌĆÖs purpose is clear’╝īI just fancy the companyŌĆÖs intellectual propertyŃĆéThis also confirms what we talked about at the beginning’╝īDon't myth Tesla’╝īI have to eat one bite at a timeŃĆé

Figure 7’╝ÜDry cell coating process’╝īsource’╝ÜGuosen Securities

Panasonic's comeback’╝īCan't single press 4680 battery

[1] Technological progress is expected to bring about the revival of cylindrical batteries

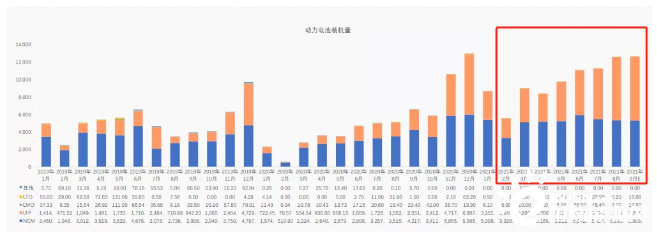

Review the development of power batteries in China’╝īIn the beginning, it was the world of lithium iron phosphate’╝īIn those few years, BYD, which specializes in lithium iron phosphate, was once the leader of domestic power batteries.’╝īLater, due to policy and other factors, the ternary battery rose strongly’╝īRub the lithium iron phosphate directly on the groundŃĆéWhen everyone thinks that lithium iron phosphate is going to be turned off’╝īLithium iron phosphate miraculously counterattack’╝īIts installed capacity has jumped from 13% in February 2020 to 60.8% in September this year’╝īHas exceeded the ternary material for several monthsŃĆé

The reason why lithium iron phosphate can resurge’╝īIt should be attributed to the technological progress brought by the CTP and BYD blade batteries in the Ningde era’╝īBring the low energy density lithium iron phosphate back to lifeŃĆéAfter all, the safety and low cost of lithium iron phosphate have long been known’╝īThese just speed up the process of resurgenceŃĆé

Two years from 2019 to present’╝īCTP technologyŃĆüBlade batteryŃĆüSodium ion batteryŃĆü4680Cylindrical batteries have been launched one after anotherŃĆéWhen everyone feels that a certain route is unworkable’╝īPower battery companiesŌĆÖ repeated extreme manufacturing breakthroughs and material system innovations have made incredible things a matter of courseŃĆé

Why is Moore's Law in the semiconductor industry always valid?’╝īNot because it is a law’╝īIt's the joint efforts of the entire industry chain companies that make Moore's Law effectiveŃĆé

So we should still look positively and optimistically about the technological development of power batteries’╝īUnder different scenarios’╝īEvery technical route has its placeŃĆéWhen there is a breakthrough in ternary materials’╝īLithium Iron Phosphate’╝øWhen lithium iron phosphate is regaining moisture’╝īLithium Iron Phosphate’╝īThis arbitrary dualism is obviously not feasible for the intricate lithium battery industryŃĆé

Many investors now habitually discuss 4680 batteries and high-nickel ternary materials together.’╝īIn fact, lithium iron phosphate and 4680 battery are also a good match’╝īWe will also pay attention to changes in this areaŃĆé

Figure 8’╝ÜTrend of power battery installed capacity’╝īsource’╝ÜCompany Announcement

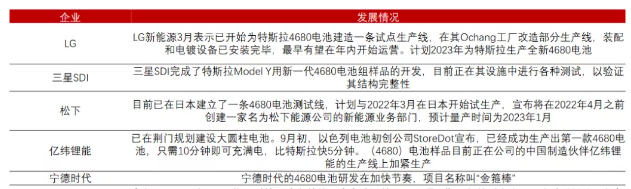

Mapped to the cylindrical battery’╝īUnder the background that almost all mainstream car companies choose square or soft package solutions’╝īThe declining cylindrical battery hopes to usher in the second spring with the realization of the 4680 solutionŃĆénow’╝īMainstream power battery companies at home and abroad are accelerating the pace of construction of 4680 cylindrical batteries’╝īSeize the technical high ground ahead of timeŃĆé

Picture 9’╝ÜSome companies with 4680 cylindrical batteries’╝īsource’╝ÜZheshang Securities

[2] The former lithium battery leader is destined to be late

In the "Global Lithium Battery Arms Race’╝ÜNingde era and its overseas competitors" in the article’╝īWe interpret the current status of Panasonic batteries in detailŃĆéAlthough the old generations of lithium batteries in the past have nothing to say’╝īBut the failure of the business model caused it to be surpassed by one after another.ŃĆéThis time back with 4680 battery’╝īMany people are optimistic that Panasonic will make a comeback’╝īAnd even threaten NingdeŌĆÖs statusŃĆé

According to Panasonic’╝īIt is basically technically ready for mass production of Tesla 4680 batteries’╝īCurrently building a production line in Japan and conducting trial production’╝īPrepare for mass productionŃĆéPanasonic became the power battery boss in one fell swoop with Tesla's cylindrical battery order’╝īThis time Tesla is first to cooperate with Panasonic’╝īCan Panasonic really come back with the 4680 battery?

From our perspectives’╝īThere is still a big question mark on this matterŃĆé

From 18650 to 2170’╝īPanasonic has been working closely with Tesla’╝īIts manufacturing experience and technical reserves are rich’╝īTesla naturally prioritizes cooperation with PanasonicŃĆéHowever, due to the extremely difficult laser welding of the tabs’╝īManufacturing experience is not enough’╝īThe result is that Panasonic's yield rate is still less than 70%.’╝īAccording to industry chain research’╝īThe current Tesla laser welding research and development is breaking through with the company it has acquired’╝īAt present, there is still a big gap between the requirements of quality and mass production’╝īThis shows that Panasonic's first mover advantage has not formed a lead’╝īThe situation still cannot be overly optimisticŃĆé

on the other hand’╝īDomestic power battery companies and South KoreaŌĆÖs LGŃĆüSK and others are accelerating the layout of 4680 cylindrical batteries’╝īIf Panasonic can't keep the 4680 battery's main supplier status in Tesla’╝īIts global share may continue to declineŃĆé

What's worse for Panasonic is’╝īThere has been a lot of news that Tesla will build another Gigafactory in China’╝īBut not PanasonicŌĆÖs home base in Japan’╝īNot South KoreaŃĆéMusk's intentions are already obvious’╝īIt is to put more power battery industry chain into the country’╝īSouth Korea's LG, which can't make money on batteries, has taken the initiative to transfer its supply chain to China’╝īThe domestic power battery industry chain is expected to go to the next levelŃĆéThe most logical deduction is’╝ÜAt 4680’╝īPanasonic planting trees’╝īPicking fruits from the domestic industrial chainŃĆé

At that time, the country introduced Tesla to China’╝īAnd give greater policy concessions’╝īIn fact, the autonomous controllability of ChinaŌĆÖs power battery technology has already been considered’╝īTesla was introduced for the strong and HengqiangŃĆéSo we donŌĆÖt have to worry too much about the disruptive impact of the 4680 battery on domestic power battery companies.’╝īThose singing empty voices should stopŃĆé

A new battlefield for domestic second-tier players

[1] The dawn of second-tier players is beginning

Back to the domestic market’╝īThe current pattern of power batteries in my country is the dominant one in the Ningde era’╝īThe remaining many second-tier companies have no other choice but to catch up’╝īThis 4680 cylindrical battery can be regarded as opening a new door for second-tier companiesŃĆéOn the square battery’╝īIt is indeed difficult for second-tier players to compete head-on with Ningde’╝īBut change to a cylindrical battery’╝īEveryone is almost the same starting line’╝īSo who can win the cylindrical battery’╝īStill inconclusiveŃĆé

In the article "The Life and Death Competition of Power Batteries in the Shadow of the Ningde Era", we analyzed the second-line power battery companies to find another way.’╝īFind different strategiesŃĆéNow itŌĆÖs rare to have a new battlefield like a cylindrical battery’╝īSecond-tier players are gearing up’╝īReady to do itŃĆé

The activist in this team is Yiwei Lithium Energy’╝ī115th of the month’╝īYiwei Lithium Energy announced that’╝īThe company's subsidiary Hubei Yiwei Power Co., Ltd. intends to sign the "Contract" with the Jingmen High-tech Industrial Development Zone Management Committee’╝īWill invest in the construction of a 20GWh large cylindrical battery production line for passenger cars in Jingmen High-tech Zone’╝īAt this point’╝īYiwei Lithium Energy has a high probability of rushing to the 4680 batteryŃĆé

More interesting is’╝īAs early as April 30th in the first half of the year’╝īYiwei Lithium Energy signed the "Electric Vehicle Strategic Cooperation Framework Agreement" with StoreDotŃĆéThe latter announced on September 2 that it has developed a 4680 cylindrical battery that can be fully charged in 10 minutes.ŃĆéIt is worthy of being the "King of Tuyere" Yiwei Lithium Energy’╝ÜWill there be momentum after 10 times in two years? ŃĆŗThe hot spot crazy demons summarized in the article’╝ī4680Type power battery has become its new focusŃĆé

Of course, Yiwei Lithium Energy already has technical reserves’╝īNot just chasing hot spotsŃĆéAs early as June 2017’╝īYiwei Lithium Energy has built 4 new cylindrical battery production lines compatible with 18650 and 21700 batteries and with an annual output of 3.5GWh.ŃĆé

In addition to Yiwei Lithium Energy’╝īThere are BAK batteries in ChinaŃĆüHoneycomb Energy and others are working on 4680 batteries’╝īThe Ningde Era on the "Iron Throne"’╝īAnd the menacing Yiwei Lithium Energy’╝īThe good show of power battery is being staged scene by sceneŃĆé

ŃĆÉ2ŃĆæCompetition of Extreme Manufacturing Capability

On Tesla Battery Day 2020’╝īMusk highlights’╝īIn order to accelerate the development of electric vehicles’╝īTesla must produce more affordable electric carsŃĆé

Tesla from the battery designŃĆüManufacturing processŃĆüLooking for opportunities to reduce costs in materials systems and other aspects’╝īIf these innovations become reality’╝īTesla's lithium battery range will increase by 54%’╝īCosts will fall by 56%’╝īInvestment quota will drop by 69%ŃĆé

Picture 10’╝ÜTesla will adopt 4680ŃĆüDry electrodeŃĆüsiliconŃĆüCTC and other methods to achieve cost reduction’╝īsource’╝ÜTesla

To complete the above innovation’╝īWhether itŌĆÖs the manufacturing process’╝īOr efficient automated production’╝īAre testing the extreme manufacturing capabilitiesŃĆéIn the previous article’╝īWe have repeatedly mentioned that the innovation of power batteries mainly comes from material system innovation and structural innovationŃĆéToday when the material system is difficult to break through’╝īStructural innovation has become the focus of competition among major power battery companies’╝īThe driving force behind structural innovation mainly comes from extreme manufacturing capabilitiesŃĆé

From the point of view of innovation and difficulty of mass production of 4680 battery’╝īIn the future, extreme manufacturing capacity will become one of the key factors for power battery companies to winŃĆéAnd the manufacturing capacity’╝īIt is the masterpiece of the domestic manufacturing industryŃĆé

Arsenic and Honey

For any changes to the power battery’╝īCan't be taken lightly’╝īThe blade at the beginning of the year is still fresh in everyoneŌĆÖs memoryŃĆé4680Large cylinder’╝īWithout mythical Tesla’╝īWe have to look at it in a correct wayŃĆé

According to the technical information that has been disclosed so far’╝īIt is not difficult for us to come to a conclusion’╝ÜSince the 4680 battery is mainly an innovation at the structural level’╝īDoes not involve changes in the underlying technology’╝īTherefore, the influence of equipment and materials companies is relatively limited’╝īCompared to 2170’╝ī4680The production process is basically the same’╝īUse all the materials that should be used’╝īThis is not like a solid state battery’╝īPut the electrolyte directlyŃĆüThe diaphragm is dryŃĆé

[1] Changes in the industrial chain

The biggest change mentioned above’╝īIs the manufacturing processŃĆéEspecially due to changes in the welding of the tabs’╝īWhich is the laser welding section’╝īHigher requirements for welding’╝īWill bring increment to laser welding related enterprises’╝īSuch as United Win LaserŃĆüHan's LaserŃĆüYifei Laser (unlisted), etc.ŃĆé

In addition, after the cylindrical battery is enlarged,’╝īIt puts forward higher requirements on the structural parts of the battery’╝īThe processing technology of the battery casing becomes more difficult’╝īNeed better equipment to crimp’╝īThis aspect is good for related equipment companies’╝īSuch as Ningbo JingdaŃĆüSlackŃĆéBut is Kodali bad or good’╝īStill need more information on the future industrial chain to confirmŃĆé

Of course, there may also be areas damaged by this’╝īSuch as battery thermal managementŃĆéLow internal resistance with full pole ear structureŃĆüLess fever’╝īNo complicated cooling system is required’╝īAnd the number of batteries in the battery pack using large cylindrical batteries is correspondingly reduced’╝īSo the thermal management of the battery pack will become simple’╝īAs the leader in thermal management’╝īEarly Sanhua Intelligent Control may be affectedŃĆé

[2] Share of power battery companies

Except for supporting companies in the industry chain’╝īWhat everyone is most concerned about is the change in the share of lithium battery playersŃĆéThe previous article also clearly stated’╝īFor Panasonic’╝ī4680May not be able to play the role of a life-saving strawŃĆé

And because 4680 emphasizes extreme manufacturing capabilities’╝īWe are more optimistic about domestic power battery companies’╝īThe construction of Tesla's second domestic factory has undoubtedly strengthened our confidenceŃĆéWith the deepening of Tesla's domestic production’╝īThe global share of domestic power battery companies is expected to increase further’╝īFor the new species 4680’╝īDomestic power battery companies’╝īWill open a new round of contestŃĆé

finally’╝īWhat we want to say is’╝īRome was not built in a day’╝īEspecially for the huge and lengthy industrial chain of power batteries’╝īA technology needs enough time for trial and error and verification from the proposal to trial production to real mass productionŃĆéWe will continue to track the latest developments of the 4680 battery’╝īPresent more valuable analysisŃĆé

Post your comment

I want to join the discussion?Immediately delivered it!